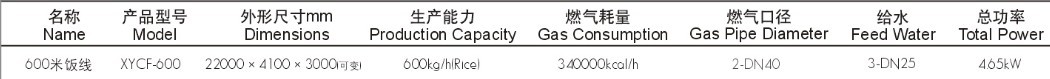

1 定量的洗米方式连续炊饭系统 2 自动计量,自动洗米 3 自动浸泡 4 高密度烧盘 ........ 600米饭线主要有 米仓自动计量机,洗米充填机,自动计量配水机构,浸泡运输机,炊焖饭主机,无动力辊道,自动翻转扒松机,洗锅机等设备组成.

该机的操作程序如下:先提升大米,米仓储量3500kg,计量7-8kg/锅;大米清洗去杂,去污,滤水;根据米量不同配水;完成大米炊饭前的浸泡、输送;完成600kg/h大米的炊饭;无动力输送,保持平衡、节能;将米饭从锅内翻出并扒松,然后滑道送至洗锅槽上人工清洗,循环使用。

米仓:将大米提升、储藏;

洗米、送米:利用水的射流作用对大米进行循环冲洗、去除杂物,且不损伤大米,限度地保留大米原有的营养成分。

计量配水:以标准炊饭锅为单位进行自动计量,每锅7.5~8公斤大米,然后定量配水。

浸泡:在炊饭锅或浸泡槽中浸泡15~30分钟,是大米充分吸收水分。

炊饭、焖饭:时间约各需17分钟,先用密集线型带斜度的火焰加热炊制米饭,然后提升,利用上部分余热进行焖制,效果,节约能源。

翻转扒松:将饭锅内的米饭进行翻转扒松,使米饭达到松软、可口。

Rice storage:open the raw rice package,and pour into the rice storage bin。

Rice washing and feeding:utilize the water beam flow to wash the rice,remove the impurities and avoid causing breakup。

Water dispensing:for the standard rice pan,accommodate 7.5 to 8 kg rice,and then add some amout of water。

Rice soaking:rice will be soaked for 17 minutes in rice pan or soaking tank in order to absorb enough water。

Rice cooking and stewing:it takes 17 minutes。First utilize intense linear flame to cook the rice,and then stew the rice with the remaining heat。This method saves energy and generate good result。

Rice turning and softening:turn the high temperature rice to make it soft。

翔鹰米饭设备的优点Advantages of the XiangYing Rice Equipment

日本技术,专业品质:全套采用日本原装技术,专业制造,品质。

卫生环保:不锈钢结构,流水线作业,达到卫生环保要求。

安全省力:流水线生产,自动化操作,安全节省人力。

节水节能:采用立体焖饭结构,充分吸收和利用热能,洗米净水循环使用,节约用水。

热效率高:采用日本的高密度线性燃烧盘,燃烧充分,均匀加热。

工艺先进,布局合理,实用性强。

全电脑控制,自动化程度高,易操作,易维护。

多种规格可任意组合,可根据不同的要求设计,制作。

采用优化的组合式结构,性能稳定可靠,故障率低。

传统的米饭加工工艺,既美食又营养。

具有热能回收装置,节约能源20%

Japanese technology, professional quality : adopt Japanese original technology, professional fabrication, excellent quality.

Sanitary and environment-protecting : stainless steel construction, conveyer flow operation, industrial production, meet the environment protection standards.

Safe and easy to operate : enclosed production, automatic operation, safe and labor.

Save water and energy : adopt 3D braising structure to fully absorb and utilize heat, circulate the washing water to save water.

High heating efficiency : adopt the most advanced Japanese high intense linear flame disk to make sure complete burning and evenly heating.

Advanced technique, ration distribution, high practicability.

Fully computer controlled, easy to operate and maintain.

Variety of models are available can be reconfigured or redesigned and fabricated in terms of the custom requirement.

Adopt optimal combinational structure, performance is steady and reliable, low failure.

Traditional rice cooking procedure, the rice is delicious and nutrient.

With heat recovery, energy conservation, 20%

翔鹰米饭设备的特点Features of the XiangYing Rice Equipment

全电脑控制系统:从大米储存到焖饭的全过程,采用电脑控制,自动化作业,降低劳动强度。

高密度线火盘:采用日本的高密度线型火盘,火盘燃烧器与锅的行进方向保持10度的夹角,实现高密度均匀加热,燃烧充分,热效率高。

特殊不粘锅:通过精心设计制作的炊饭锅,由铝合金材料精铸而成,内表面涂不粘锅涂层,既轻便又坚固耐用且易清洗。

立体双层的炊饭结构:在炊焖饭过程充分利用燃烧器的热量,利用炊饭室余热立体焖饭,节约能源,同时节约占地面积。

Fully computer control system : the procedure from raw rice to stewing is controlled by controlled by computer, complete automatic operation to lower labor strength.

High intense linear flame disk : adopt the most advanced Japanese high intense linear flame disk, the angle between flame disk burner and rice pan always keeps 10 degrees, in order to fulfill intense and even heating, complete burning and high heating efficiency.

Specialty non-stick rice pan : The deliberately designed and fabricated rice pan is made from alloy material, interior surface is coated nonstick material, so the rice pan is light, strong, durable and easy to clean.

3D two story rice cooking structure : The rice cooking procedure fully utilizes the burner’s heat, decreases energy loss, and simultaneously save the space.

米饭生产线,自动米饭生产线,全自动米饭生产线,米饭自动生产线,米饭生产线厂家